FULLY AUTOMATIC AND FLEXIBLE

SPECIAL MACHINE CONSTRUCTION

Case Study No.014

Migros distribution centre

Initial position

Cardboard boxes are filled, labelled by hand and dispatched. The boxes can no longer be used after processing and end up as waste.

Customer requirement

In order to implement a sustainability concept, returnable containers must be able to be sent back and forth, used several times and labelled for different contents.

FULLY AUTOMATIC AND FLEXIBLE

SQUIX LABEL PRINTER

Solution

AREA OF APPLICATION

PRACTICAL EXAMPLE

FULLY AUTOMATIC AND FLEXIBLE

SPECIAL MACHINE CONSTRUCTION

Case Study No.017

Ceposa AG

INITIAL SITUATION

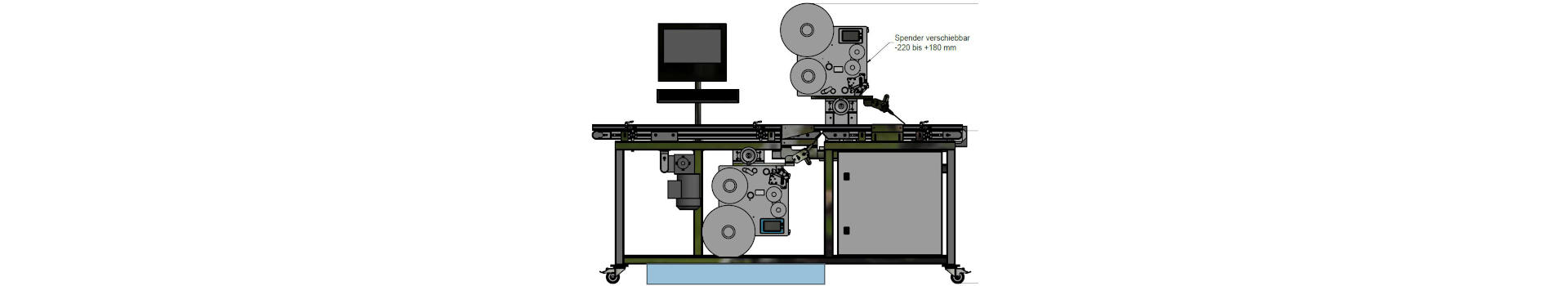

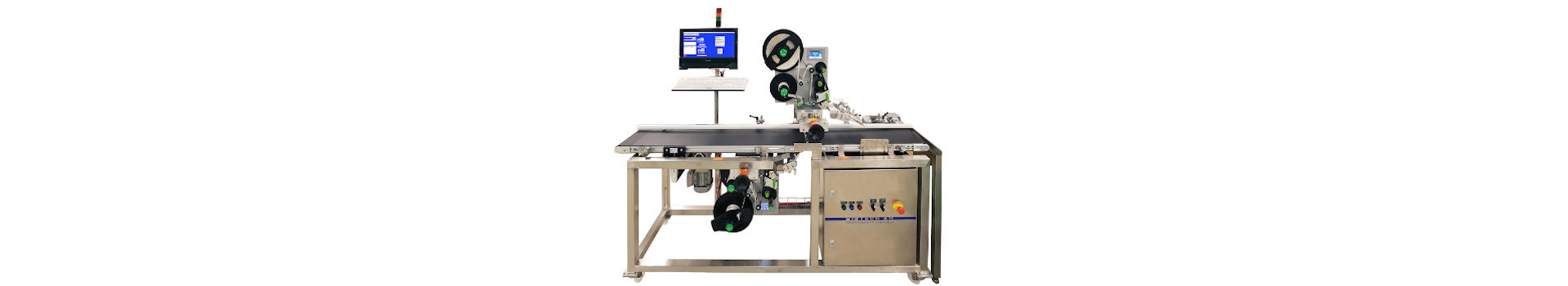

The existing labelling machine and software were getting on in years. The packaging with different sizes and heights should continue to be labelled. The labels are printed with variable data and must be able to be applied from below or from above or simultaneously from below and from above.

CUSTOMER REQUEST

The customer already has several SIGTECH products in operation and is extremely satisfied because he has a hardware and software solution “from a single source”. The new system is to be introduced in addition to the old one and can be controlled using the same software.

FULLY AUTOMATIC AND FLEXIBLE

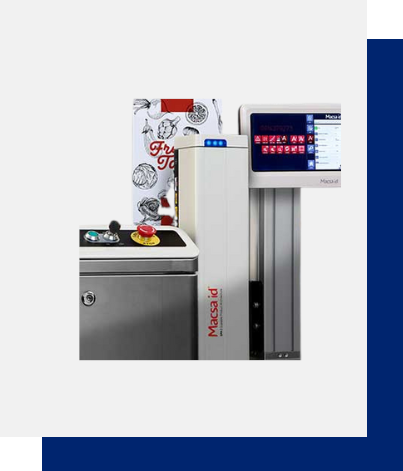

Hermes Q

Solution

AREA OF APPLICATION

PRACTICAL EXAMPLE

FULLY AUTOMATIC AND FLEXIBLE

SPECIAL MACHINE CONSTRUCTION

Case Study No.021

HÜGLI NAHRUNGSMITTEL

OUTSIDE LABELLING

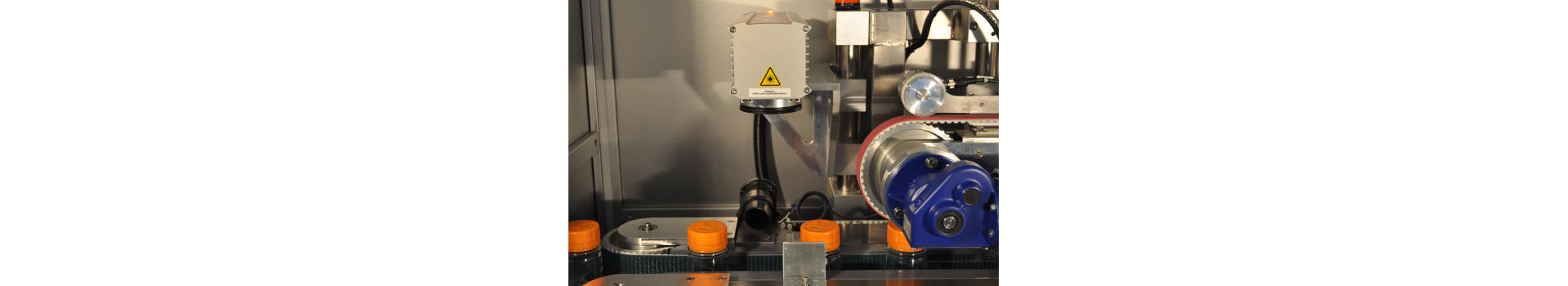

The plastic lids of the spice jars are not labelled.

As they are provided with small holes for adding spices, labelling is out of the question.

CUSTOMER REQUEST

All plastic lids (three different colours and two different formats) are to be labelled at a high speed of 2 pieces per second. This is only possible using a laser.

FULLY AUTOMATIC AND FLEXIBLE

Fibre laser F-9030 Pulsed Duo

Solution

AREA OF APPLICATION